Quiet Solutions That Speak Volumes

Sounds Like a Plan

Cattani has several quiet dental suction solutions ranging from the Cube range through to the Blok-Jet Silent systems. We also have options available for compressed air with our Q series compressors and purpose-built designed acoustic housings for AC100 through to AC300. With a broad range of solutions available, it is always worth evaluating the advantages and potential limitations that are considered in the dental surgery design phase. To begin, a basic level of understanding of the implications of sound and noise is necessary.

The Science of Sound

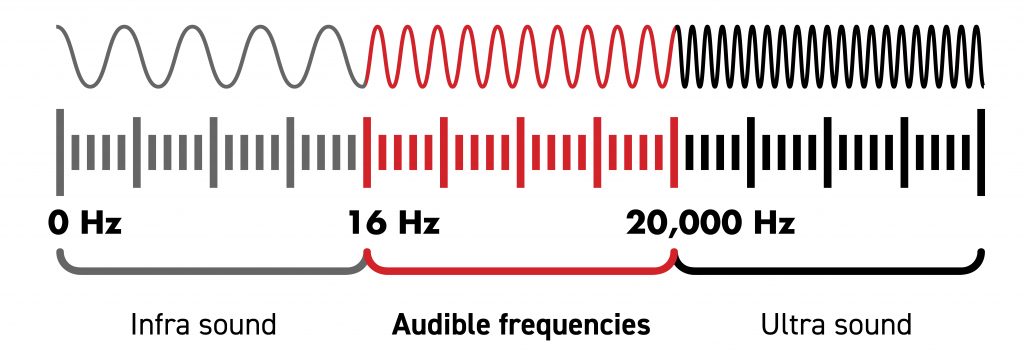

All sound is measured in decibels (dB), which includes a range of lower and higher frequencies. The human ear cannot hear certain frequencies. Weighting can be applied to decibels to account for the relative loudness of sounds as perceived by the human ear. This is expressed as a dB(A) number.

It is for this reason Cattani publishes sound pressure levels for their equipment expressed as dB(A), which have been tested to a suitable EN standard.

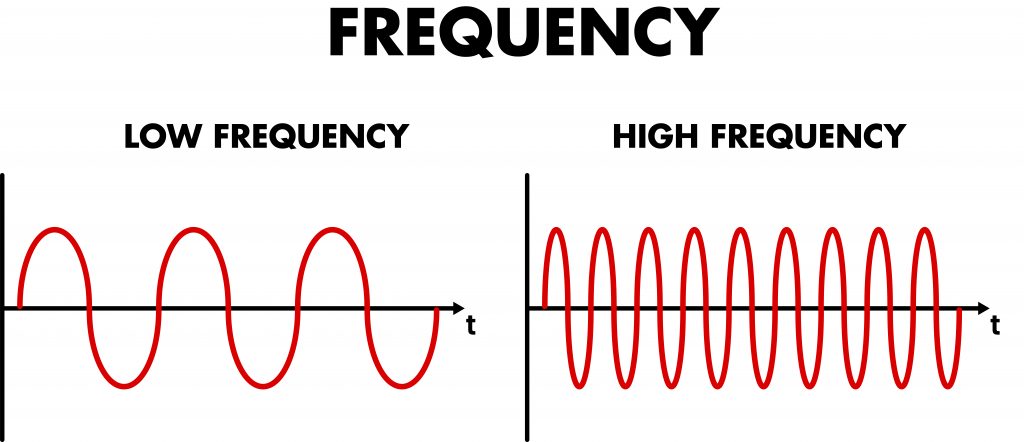

The impact of frequency also must be considered in the design phase. Frequency is a measure of how fast a sound wave oscillates. When discussing noise, the terms "high frequency" and "low frequency" refer to the range of frequencies present in the noise signal. These are expressed in Hertz (Hz).

High-frequency noise refers to signals containing a significant proportion of energy at higher frequencies. These frequencies are generally perceived as having a higher pitch.

• High-frequency noise may include sounds like the whirring of a fan.

Regarding the frequency range, high-frequency noise typically refers to frequencies above 5 Kilohertz (kHz), extending into the ultrasonic range that is not audible to humans. Low-frequency noise, on the other hand, consists of noise signals with significant energy content at lower frequencies. These frequencies are typically associated with lower-pitch sounds.

• Low-frequency noise can include the thump of a bass speaker or the hum of an air conditioning unit.

Low-frequency noise is generally below 500 Hertz (Hz).

Why Is This Important?

Key perceptual differences between high and low-frequency noise are that high-frequency noise is often perceived as sharp, piercing, or shrill, whilst low-frequency noise is usually described as deep, rumbling, or booming.

High-frequency noise tends to be more directional and can be easily obstructed by objects or barriers. Low-frequency noise, however, can penetrate through walls, floors, and other structures due to its longer wavelength. Think of a house party; it is usually the bass in the music that is more noticeable.

High-frequency noise can be effectively masked by other sounds in the higher frequency range. In contrast, low-frequency noise can be more challenging to mask because it often persists even in the presence of other sounds.

Taking Control of Noise

The methods and techniques of controlling high and low-frequency noise can differ. Sound absorbers and barriers that attenuate (reduce) higher frequencies may be effective for high-frequency noise. Low-frequency noise control often involves a combination of sound insulation, vibration isolation, and structural modifications to reduce the transmission and impact of low-frequency vibrations.

Understanding the frequency content of noise is important when addressing noise-related issues, as it helps determine appropriate mitigation strategies and control measures. The selection of noise control measures often depends on the noise source's specific characteristics and frequency distribution.

Amplification, When It’s NOT Music to Your Ears.

Plant room design can impact the ambience of a workplace; even when a quiet equipment solution has been selected, the limitations or design of the space it is housed can undo the selection process.

A good illustrative example is when an acoustic guitar is played. When the guitar is strummed, energy from the vibrating strings is transferred through the bridge and saddle to the soundboard. The soundboard then acts as a diaphragm, vibrating and displacing air inside the body cavity. This displacement of air creates pressure changes that result in sound waves. The sound waves travel through the sound hole in the guitar's body, amplifying the string sound.

The same can occur when placing equipment in a space like an enclosed cupboard without appropriate noise reduction treatment. This can cause the sounds to be amplified.

Remember!

-

-

High and low-frequency sounds require different solutions to mitigate noise effectively. When in doubt, please get in touch with Cattani to provide guidance on our range of products.

-

An Acoustic Engineer can also be commissioned to provide appropriate noise mitigation solutions for the design and construction of the plant room or plant equipment location should noise factors be a significant concern.

-

Cattani Solutions: Smart And Quiet

In dental clinics, employing noise-reduction plant room solutions is vital. This not only enhances patient comfort by reducing disruptive sounds but also promote workplace health and safety. Lower noise levels help mitigate auditory health risks for dental professionals and foster a peaceful environment conducive to effective communication and focused attention, thereby improving the overall quality of dental care.

Smart CUBE Series

Starting at 59 dB(A)

Imagine a quieter, more efficient workspace with Cattani's SMART Cube series. Designed with the dental practitioner in mind, this innovative dental plant room equipment transforms your noise-sensitive environment while enhancing your operational efficiency. Here's why the SMART Cube is exactly what you need:

-

50% Noise Reduction: Acoustic housing design halves perceived noise.

-

Lower Operating Costs: The compact design uses a smaller motor with the same performance as its predecessors, translating into significant energy and cost savings.

-

Self-Protection Mode: In case of functional anomalies like fluid overloads or power surges, the unit automatically switches to self-protection mode.

-

Environmental Sustainability: Since 2015, our SMART systems have significantly reduced raw material usage.

(Blok-Jet Silent 2 pictured)

Blok-Jet Silent 1 & 2

Starting at 55 dB(A)

The Blok-Jet Silent 1 & 2 solution is to stack the units inside their own cabinet. With the Blok-Jet Silent 1 serving 1-2 chairs and the Blok-Jet Silent 2 serving 3-4, it is an excellent option when noise mitigation is a priority. The cabinet also has a very small footprint and stands on caster wheels for easy positioning and service access.

-

Compact: The size of a fridge

-

Ultra-Quiet: Starting at 55 dB(A)

-

Mobility & Security - Lockable wheels and cabinet doors

-

External Display Panel: Shows compressor and suction status

Q Series Dental Compressors

Starting at 63 dB(A)

Our Q series of compressors significantly reduces noise levels, making them an ideal choice when equipment is proximate to the surgery. Our antibacterial HEPA H14 filter (High-Efficiency Particulate Air), comes standard with all dental compressors and helps deliver quality results by removing 99.975% of solid and biological particles down to 0.3 micron.

-

7-Year Warranty: Full parts and labour

-

Acoustic Hood: For significant sound reduction

-

Certified Protection: Food grade resin coated tank

-

Added antimicrobial protection: With Biocote® silver-ion lining in the tank

Click below to see our quiet solutions.

OTHER STORIES