How Cattani Oil-Free Compressors Protect Your Dental Handpiece

According to Allied Market Research data, the global dental handpieces market size was valued at US$1.6 billion in 2021, and is projected to reach US$2.7 billion by 2031, growing at a compound annual growth rate of 5.5% from 2022 to 2031.

The growing demand can be attributed to several factors, including the increase in overall demand for dental treatment, technological advancements, and even growing investment in dental care in developing nations.

Because of the increasing need for dental handpieces, professionals are forced to think how best to not only invest in equipment, but also invest time into understanding maintenance to extend the life of their dental handpiece equipment. Here are some commonly used procedures for equipment maintenance.

Maintenance best practices for your dental handpiece

Lubricate the handpiece – Lubrication oil helps prevent wear on the handpiece’s internal components. Be sure to use a sufficient level of oil to complete the lubrication process to prevent damage to components such as the ball bearings.

Flush the handpiece – While this may seem contradictory to the previous point, it is crucial that you do NOT go overboard with the oiling. After the handpiece has been lubricated, flush the handpiece to expel any excess oil from the device to prevent clogging or build-up of debris and contaminants that can affect the bearings.

Clean fibreoptic surfaces – By doing so with the appropriate solutions, this helps maintain the quality of light that can be affected by debris build-up.

External cleaning - Clean the outer casing of handpiece with the appropriate cleaning tool and be sure not to submerge the handpiece in any liquids.

Sterilisation: Dental handpieces should be thoroughly sterilised between patients to prevent the spread of infection as normal practice.

Correct storage – Store the handpiece in a cool and dry area, ensuring it has been completely cooled down and ready for use. Do not speed up the cooling process through ways such as running it through cold water as this can damage the handpiece.

Each handpiece manufacturer will have specific maintenance requirements for their products, ensure you are aware of their approved processes.

The most overlooked maintenance tip

One of the most overlooked aspects of dental handpiece preventative maintenance, is not part of the actual handpiece at all. It is simply this:

Check to ensure you are using an oil-free dental compressor.

How oil contamination can damage your dental handpiece

Residual oil within the handpiece can cause build-up and cause clogging, especially in equipment that applies air polishing. An example of this is a Prophy Jet, which is an air polishing prophylaxis system that uses air, water, and powder to remove dental plaque, soft deposits and stains whiles polishing teeth in a minimally invasive way.

The differences between Prophy Jet and traditional polishing equipment include:

- Quieter treatment: the elimination of the drill-like noises can make the treatment less stress-inducing, providing the patient with a more pleasant experience.

- Non-contact treatment: the Prophy Jet applies high-pressured water to remove stains and soft debris from teeth, instead of a rotating rubber cup which is traditionally used.

- Powder over pastes: the Prophy Jet applies a combination of compressed air, water, and powder to remove stains, whereas traditional instruments use abrasive pastes for the desired outcome.

Clogging

Particularly with the use of prophylaxis systems, it is important to understand that excess oil or powder remaining in or on the head of the handpiece, or other parts such as the coupling of chamber unit, powder chamber, or powder cap can cause clogging in the handpiece.

Overheating

As mentioned earlier, lubricating the handpiece is an important process. However, it is critical not to oversupply the handpiece with excess oil as it could impact the operation of the handpiece. This may cause the handpiece to overheat, which may lead to further damage to the ball bearings.

Of all the common tips for looking after your handpiece, preventative maintenance measures may not the first to come to mind. To put your mind at ease, the use of oil-free compressors can prevent oil contamination and help your handpiece deliver continuous and oil-free dry hygienic dental air.

International Standards Compliance

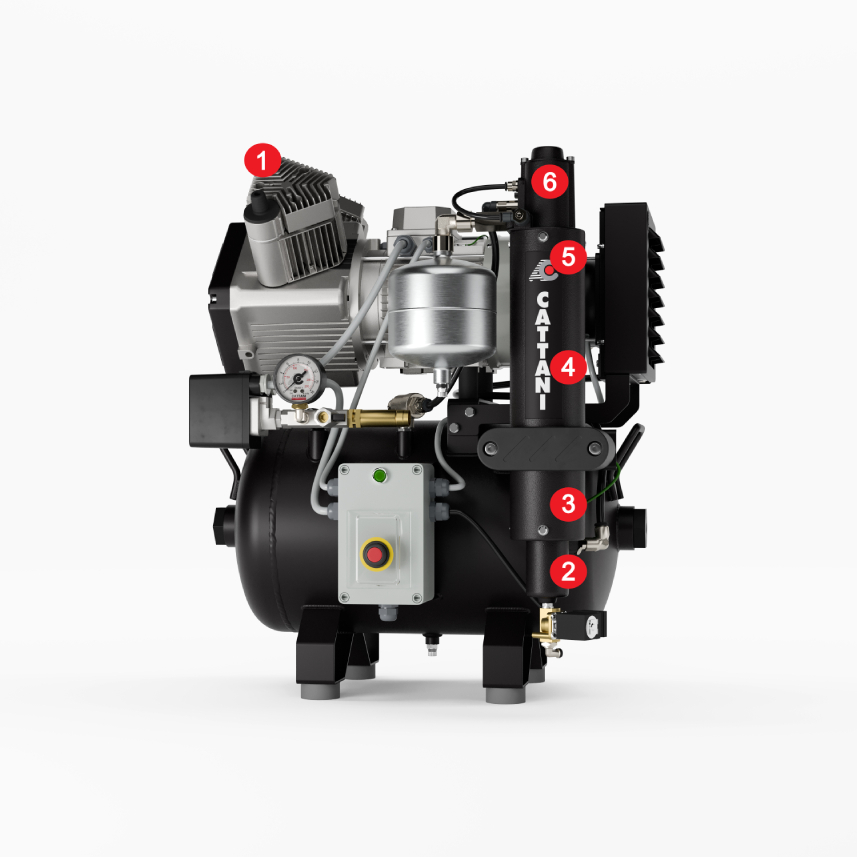

Cattani compressed air quality is supported by an ISO 8573-1 standard compliance with Purity Class 2:4:2. This class level can be divided into the following:

Particle class 2, Humidity class 4 and Oil content class 2.

PARTICLE CLASS 2

The number of particles in the dental air of

the size between 1μm and 5μm is ≤ 100/m³

HUMIDITY CLASS 4

The pressure dewpoint is ≤ +3°C at 20°C

medium temperature and at 7.0 Bar

constant system pressure, (equivalent to an

atmospheric dewpoint of ≤ -21°C).

OIL CONTENT CLASS 2

The oil content of the dental air is

≤ 0.1 mg/m³

With HEPA H14 filtration standard on all AC Compressors, we provide you a market-leading 7-year warranty on our compressors, including full parts and labour.

Click below to learn more about Cattani’s Six-Stage Dental Air Purification System.

Alternatively, call us on: +61 3 9484 1120

OTHER STORIES