These WHS measures are designed to protect most but not all people. The risks from workplace noise must be eliminated or minimised so far as is reasonably practicable. This led Cattani engineers to develop an innovative solution that not only reduces noise but could help save space.

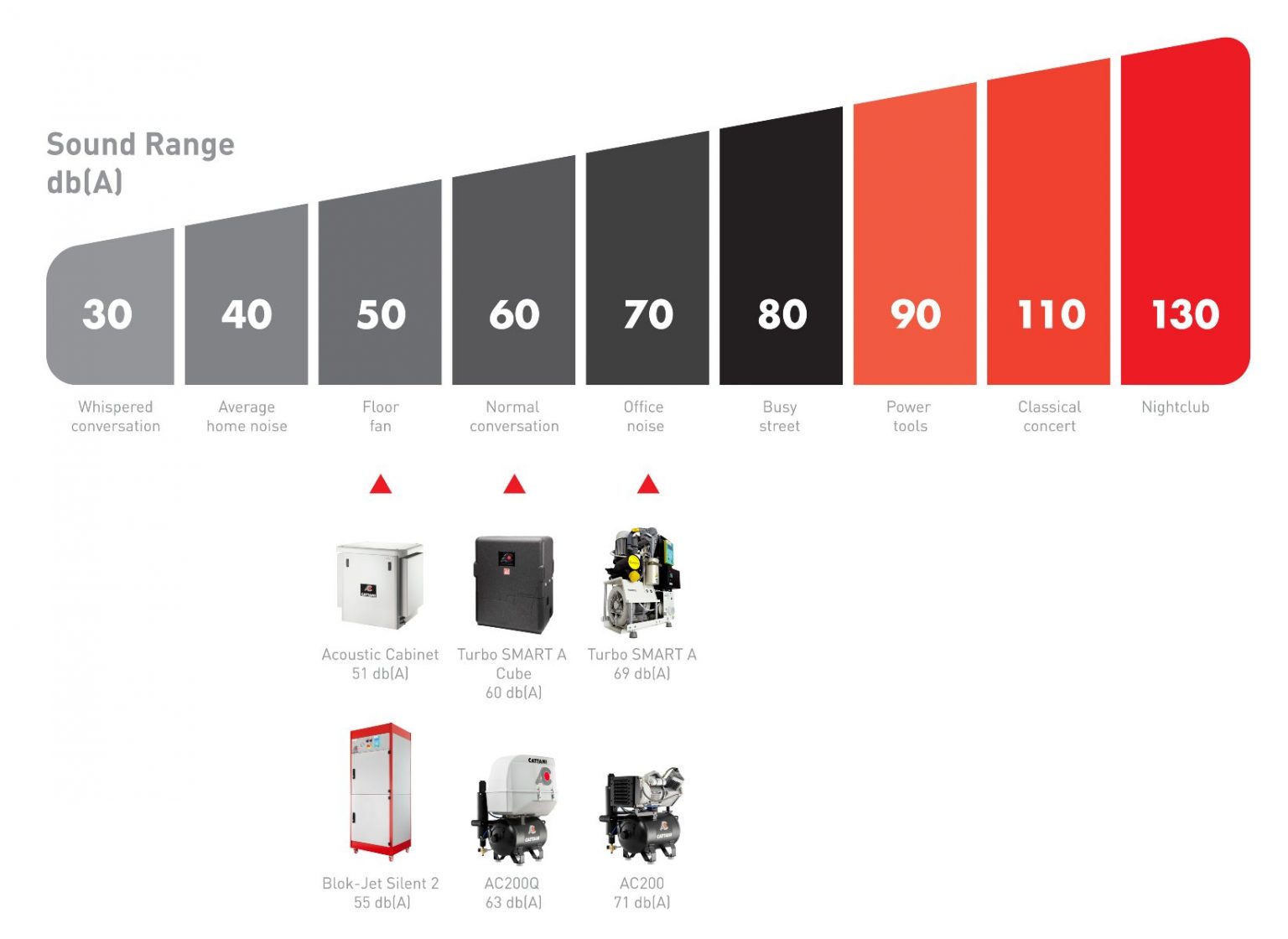

Cattani solutions: Sound reduction capabilities

The Blok-Jet Silent solution is to install the compressor and suction units inside a sound-absorbing cabinet. Serving up to four chairs and is ultra-quiet, it is the ideal solution when noise mitigation is a priority, and space is at a premium.

Blok-jet Silent 2

55 dB(A)

(With AC300 & Turbo SMART B)

Sound Reduction

18.5 dB(A) – Compressor

14 dB(A) – Suction

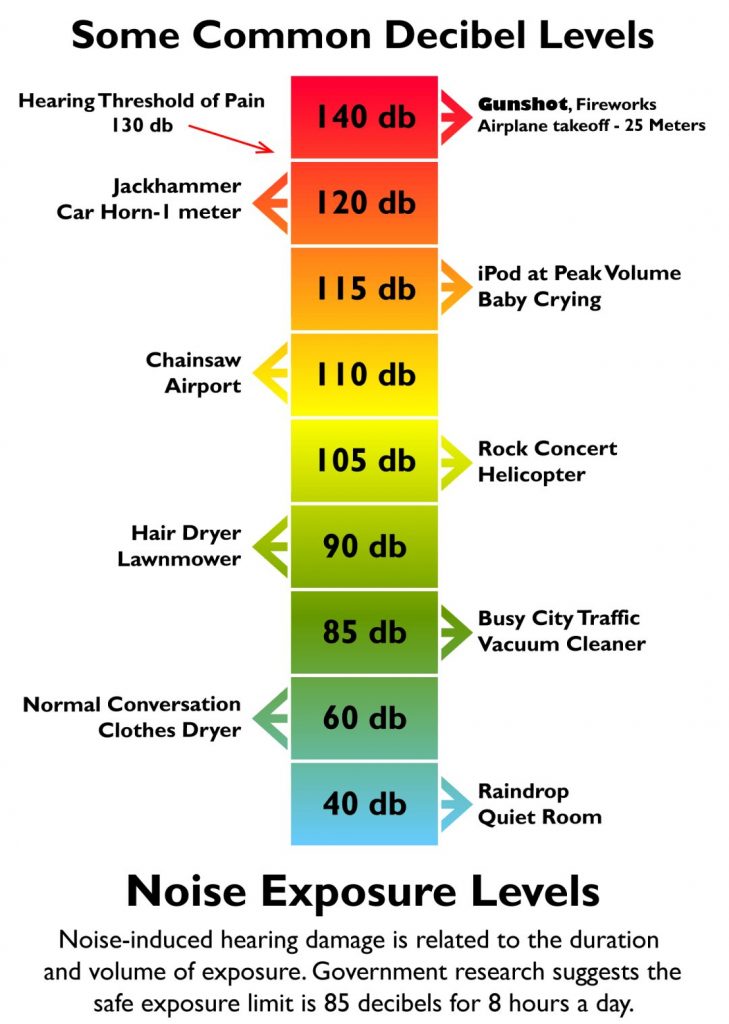

Note: Sound technically doubles with every 3 dB(A) increase, however, the human ear will only perceive a doubling of sound when it increases by 10 dB(A).

At Cattani, we offer a range of sound reduction options for different solutions. From acoustic hoods (Q series compressors) to fully enclosed acoustic and temperature-controlled cabinets, through to SMART Cube suction series with acoustic housing.

These are only a few components of the N - NOISE principles and dental practitioners are not expected to memorise the entire Cattani P.L.A.N.T Principles™. That is why our knowledgeable Cattani distributor network has undertaken comprehensive training to help you strive towards 100% reliability. It is this commitment from our local partners that have helped us deliver the finest dental air technology to you for more than 35 years in Australia.

At Cattani, our performance cuts through the noise.

CONTACT MY DISTRIBUTOR

Or

Call us on 03 9484 1120.

Are you ready for more P.L.A.N.T room love?

In the coming weeks, we will be releasing more updates on P.L.A.N.T and +S Service (After Care). Stay tuned by following us on LinkedIn.

PREVIOUS ARTICLE NEXT ARTICLE